EXPERTLY CRAFTED WITH CLARITY AND INTEGRITY, WE TAKE PRIDE IN EVERY STAGE OF THE PRODUCTION PROCESS.

Our story starts with Goda Ram, a barley farmer from Bundi, Rajasthan. In this arid region, farmers remain dependent on natural precipitation, including a timely and abundant monsoon. For the past four generations, Goda Ram’s ancestors and family have grown barley on a modest plot of land. After hand harvesting the crop using the six-row cultivated method, it is sent to expert maltsters at Soufflet and Barmalt who select the best quality.

Only the finest-quality barley is steeped in water and spread out onto malting floors to germinate. To prevent heat from building up during the germination process, the barley is turned regularly to activate enzymes that will help convert starch into sugar during the mashing process. After about a week of germinating, the barley–now called green malt–goes to the kiln to dry. This halts the germination process. During the roasting process, heat is maintained below 70° C to keep the enzymes active.

The dried malt is then ground into a course flour called grist. The grist is mixed with hot water in the mash turn in three stages, with temperatures starting at 67 degrees C and rising close to boiling point. Stirring the malt helps convert the starches into sugar. After mashing, the sweet, sugary liquid that results is called wort. The spent drains–known as the draff–are processed into cattle feed.

To begin the fermentation process, the wort is cooled to 20 degrees C and pumped into washbacks. Yeast is added, which feeds on the sugars, producing alcohol and small quantities of other compounds known as congeners. During this process, carbon dioxide is produced and the wash froths vigorously. To prevent overflowing, revolving switchers cut the heat of the liquid. After two days, the fermentation subsides. At this point, the wash is about 6-8% alcohol.

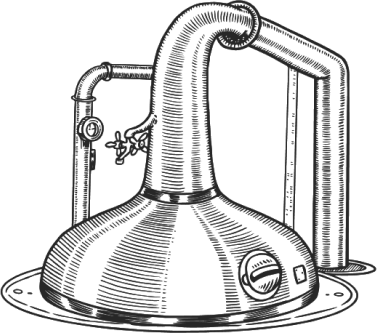

The shape of the pot has a mysterious, but important influence in the making of the malt whisky. In the distillation process, the still is heated to below the boiling point of water as the alcohol and other compounds vapourise and pass over the neck. The distillate passes through large copper coils immersed in cold water, where the vapour is condensed into a liquid.

The wash is distilled twice: in the first stage, it is done to separate the alcohol from the water, yeast, and residue. The distillate from the wash still, known as low wines, contains about 20% alcohol by volume. This is used for the second distillation in the spirit still.The distillate coming out of the condensers of the spirit stills contains three types of liquid; Heads, Tails & the Heart. Only the pure center cut or the heart of the run, which is about 68% alcohol by volume is finally collected in the spirit receiver as new make spirit.

The stillman tests and judges the distillates. The newly distilled, colourless and fiery spirit is reduced to maturing strength, 63% alcohol by volume. It is then transferred into oak casks which may have previously contained wine, bourbon, or sherry. The maturation process begins, and the whiskey becomes smoother, gains flavor, and colour from the cask. During this phase, some of the higher alcohols turn into esters and other complex compounds, which subtly enhance the whisky’s unique flavor.

Blending is a delicate art. The master blender begins by nosing samples in tulip-shaped glasses and then carefully selects from a wide palate of ex bourbon first fill, virgin oak, ex-wine and ex-sherry casks. Different malts, both peated and non peated, are considered in combination and are then left to proverbially marry in casks. Once their union is smooth and natural, the process of bottling begins. This is the final step in the process of making this Whisky, which is one of the best single malt blends in India.